What kind of rotary joint is qualified?In fact, every rotary joint before the factory from the assembly to the test will pass the layers of checks, to ensure the quality of qualified, so that every new and old customers can be at ease to use.

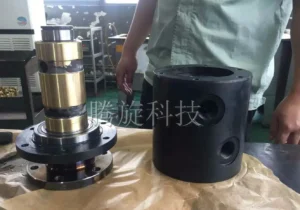

Today Tengxuan technology will show you the assembly workshop, in-depth understanding of the hydraulic rotary joint production process.

1、Assemble

The assembler installs the hydraulic rotary joint in strict accordance with the work instruction.

Installation steps: 1. Deburring; 2. Cleaning; 3. Install the end cover 4. Install the bearing (1) 5. Install the shell 6. Install the bearing (2) 7.Install the circlip 8.Install the end cap.

Pressure test

The installed hydraulic rotary joint shall undergo pressure test to test whether the oil pressure reaches a certain range, generally reaching 20mpa and qualified.During the test, it is necessary to pay attention to: (1) whether there is sand hole in the shell; (2) whether there is oil leakage on the surface of the joint.

Leakage detection

Quality management professionals to measure leakage, allow leakage control in less than 300 ml, 1 minutes to achieve qualified leakage;Not to leak range should be repair anew analysis reason until qualified.If is greater than the leakage will not be able to meet the customers’ equipment operating conditions, directly affect the use effect.

After understanding the production process of hydraulic rotary joint, we should not only choose qualified products when buying, but also choose professional rotary joint manufacturers, Tengxuan science and technology has been winning the trust and support of the majority of users with quality and service, established a good reputation in the market.

We welcome you to contact us for immediate inquiry anytime and look forward to work with you!